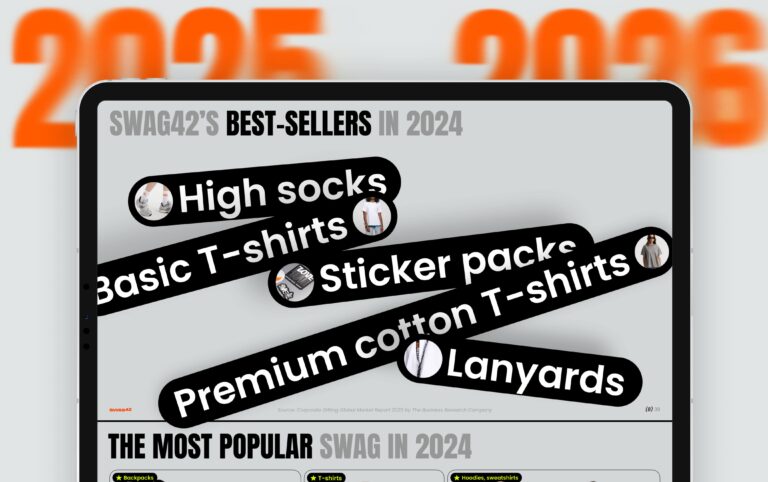

What is the difference between forgettable merch and the one people want to wear and keep? The answer lies behind the scenes of merch production, where every stitch is carefully crafted.

Welcome to the Backstage, our blog series that takes you through Swag42’s merch production process. In this first article, we spoke with Ludmila Guschinskaya, the Head of the Swag42 Laboratory, to understand how fashion merch is born—from a sketch to a premium-quality product worth every cent.

The Laboratory is part of Swag42’s Warsaw office. It’s a fashion house where new models are developed, tested, and fine-tuned to achieve top quality and perfect fit. This is where the magic happens—and Ludmila leads that magic.

Interview with Ludmila Guschinskaya

Hi Ludmila, can you tell us about your role in Swag42?

Hi! Sure. I am the Head of Laboratory, and I manage communication within in-house production projects, make key decisions, and plan the production team’s workflow. Our Lab often works with ultra-tight deadlines—sometimes just 1-3 days from project start to shipment. My job is to process all the incoming information so tasks are well-defined and the team can focus on making merch without distractions.

What kind of work does the Lab do?

Swag42 creates unique merchandise, including custom models and creative branding options. This kind of work needs a dedicated creative space, which is our Lab.

Overall, we have two merch production directions. First, we develop new models—sometimes entirely new, sometimes updated versions of existing designs but with different materials, finishes, or construction. Everything gets tested to ensure quality: fabrics, patterns, and constructions.

Second, we create samples for client projects. Clients want to see and feel what they’re ordering, so we make these samples in-house.

Can you tell us about the history of the Lab?

The Lab has been part of Swag42 since the first day. In the early days, we had a small cutting table, four sewing machines, and a tiny space for our creative experiments. But we had big plans for in-house merch customization and production even.

That same year, we added new equipment: a bag and backpack-making machine and—very importantly—an embroidery machine. This equipment was a game-changer, allowing us to experiment with branding and develop custom designs in-house.

So, what do you have in 2025?

By 2025, the lab had doubled in size, both in space and headcount. Today, we have:

- A fully equipped cutting and sewing department

- Dedicated embroidery and printing areas for merchandise branding

- A stock of selected materials for fast sample production

- A team of 8 professionals who create merch

The Lab feels more like a fashion house with a whole creative process:

Today, Swag42 Lab has professional equipment and software for pattern making, a plotter for printing patterns and layouts, a fully equipped cutting area—including rotary cutters and a large table for fabric spreading and cutting—and 11 sewing machines, universal and specialized.

All merch production equipment is professional and industrial. We also have an embroidery machine, a steam and heat area, accessory installation devices, and various supporting tools from scissors to mannequins. The printing room has a cutting plotter and a heat press for transferring prints.

What branding options do you offer within merch production?

We offer many branding options—colored fabrics, custom labels, patches, pullers, buttons, etc.—but for most projects, our clients choose embroidery and printing.

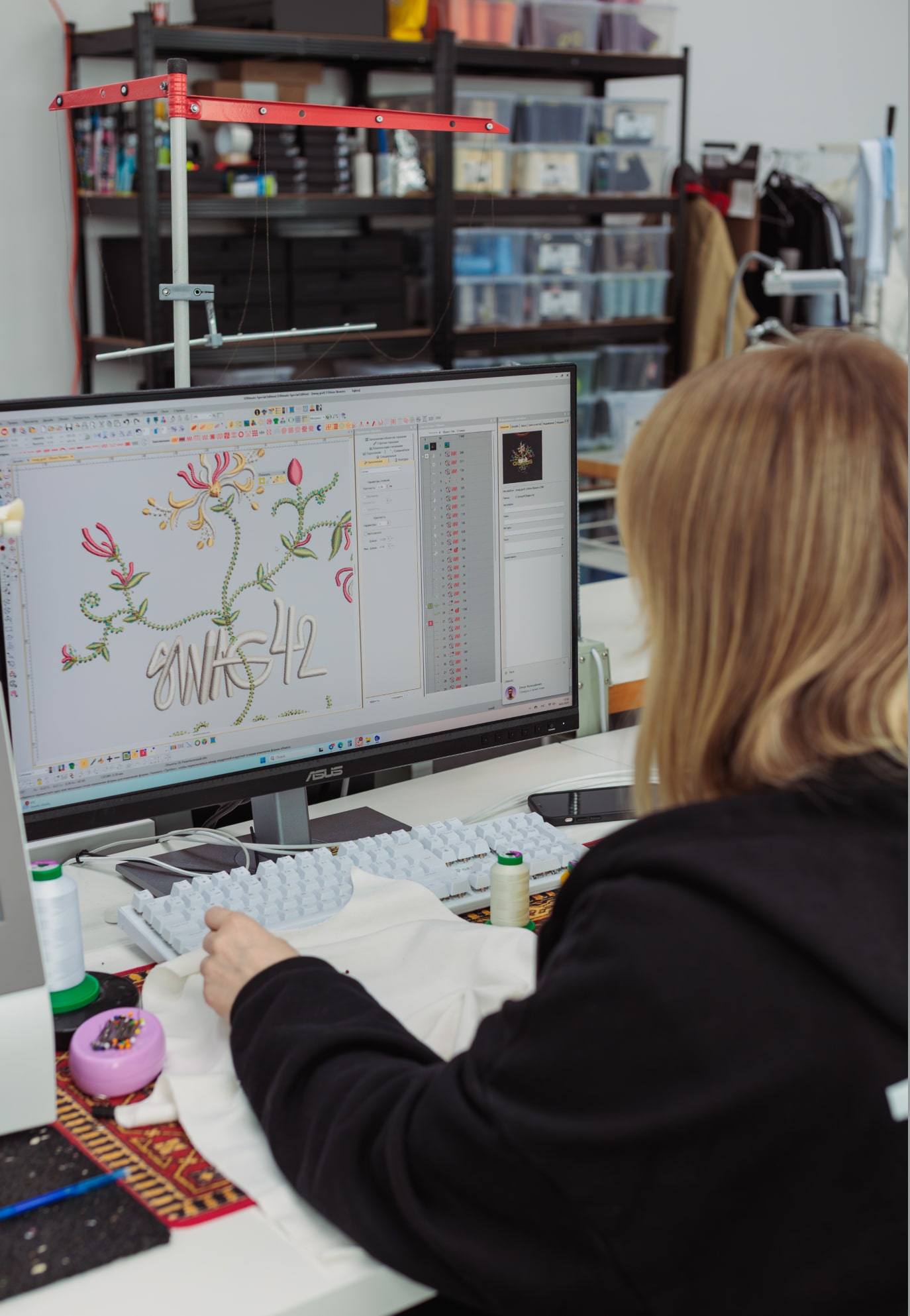

Therefore, the laboratory has dedicated areas for embroidery and printing. The embroidery area allows us to create custom embroidery designs and programs, while the printing area handles Flex and DTF printing for small orders (up to 150 units) and samples. We also have a cutting plotter and heat press here.

How do you create a new merch model?

Tanya Tereshchenko, the Creative Director, and Sandra Bondare, the Co-founder and Head of the Fashion Department, inspire all merchandise design ideas.

We usually get a digital brief from them with sketches, references, and fabric preferences. The pattern maker then starts building the first pattern while we are sourcing fabrics.

Once we sew the first sample, we test it on a model and make adjustments. Patterns and materials often undergo several changes before we’re happy. Then, we grade the pattern for all sizes, test the fit on extreme sizes, finalize branding and photos, and finally, add the item to our catalog.

Product photoshoots

What about client samples?

It’s a similar process, just more collaborative. We get a brief from the sales manager along with branding files from the graphic designer. We cut, sew, and adjust based on the client’s needs.

Once the sample is ready, the most interesting part of merch creation starts—together with the client, we change details, adjust branding, and sometimes even change fabrics or the entire model. Once it’s perfect, we finalize the specs and send them to a manufacturer for the full batch.

What makes your Lab special?

People. We are a close-knit team, like a family. There is no drama—just support and smooth collaboration. Every product is the result of shared creativity and teamwork.

What sets us apart is our approach to every item, the energy and care we put into each piece, and the fact that everyone here is a real pro—curious, creative, and constantly improving.

What are your most outstanding projects?

It is a question for a separate long conversation:) One of the recent inspiring projects was a custom uniform T-shirt for the corporate football team. It was an all-over printed sublimated T-shirt, and together with the client, we delicately fine-tuned every stitch and adjusted the construction for the printed elements. It required the whole team to brainstorm how to design merch and reconstruct the work. But the client was happy.

Another interesting project was for Fundraise Up. They wanted custom travel pillows and poncho towels with the corporate mascot, a unicorn. We fixed the details through several iterations, specifically changed the corn fabrics and design to achieve specific form and color, experimented with labels and pullers.

The customer enjoyed the products and returned with another idea: the all-over sublimated Hawaii shirt. These items soon appeared in the Swag42 catalog, with custom branding options, of course.

What do you aim to achieve in the next year?

We’re focused on speed and quality of merch creation. We aim to keep optimizing processes to reduce production time without compromising quality. Last year, we cut our sample production time in half and optimized our material sourcing based on demand, which sped up sampling and added flexibility. And we plan to get even faster this year.

Additionally, we never stop researching new customization options and will offer more and more creative branding approaches.

Is there a part of your job that’s important, but not so visible?

One of my role’s most important—but often overlooked—parts is maintaining team spirit. I always remind the team of their impact: “Look—this is your work, your contribution.” That’s how we stay motivated and energized.

Conclusion

As you can see, the quality of materials, custom approach, precise work, and hours of fine-tuning stand behind the merchandise that people want to wear. In the following article, we’ll take you deeper into the embroidery and printing rooms.

You will discover printing techniques and embroidery nuances, and which branding option is optimal for your gifts.